The Logistics

Logic.

Replacing "Spreadsheet Chaos" with a streamlined Order Fulfillment OS for a global luxury brand, reducing operational errors to near zero.

Growing Pains &

Spreadsheets.

Luca Faloni was scaling fast, but their operations were stuck in the past. Reliant on basic Shopify features and manual Excel trackers, the warehouse was becoming a bottleneck for the brand's luxury promise.

The "Shopify Limit"

The Issue: Shopify is great for selling, but terrible for enterprise inventory management.

The Friction: Warehouse staff were manually printing labels and cross-referencing Excel sheets to find items. This manual "Pick & Pack" process was slow and prone to human error.

Inventory Blindspots

The Issue: No single source of truth.

The Friction: "Phantom Inventory" items showing as in-stock online but missing from the shelf - was leading to order cancellations and damaging the brand's reputation with high-net-worth clients.

From "Screen" to "Floor".

We didn't start in Figma. We started on the warehouse floor. I used a Service Design approach, mapping the physical movement of goods to build a digital twin of the workflow.

The "Gemba" Walk

I shadowed warehouse operators for days. I realized the bottleneck wasn't the software speed, but the physical act of walking back to a computer terminal to check orders.

Untethering the Staff

Insight: The solution had to be mobile.

We shifted the "Picker" workflow entirely to handheld Zebra devices, allowing staff to scan and verify items directly at the shelf.

Control Tower View

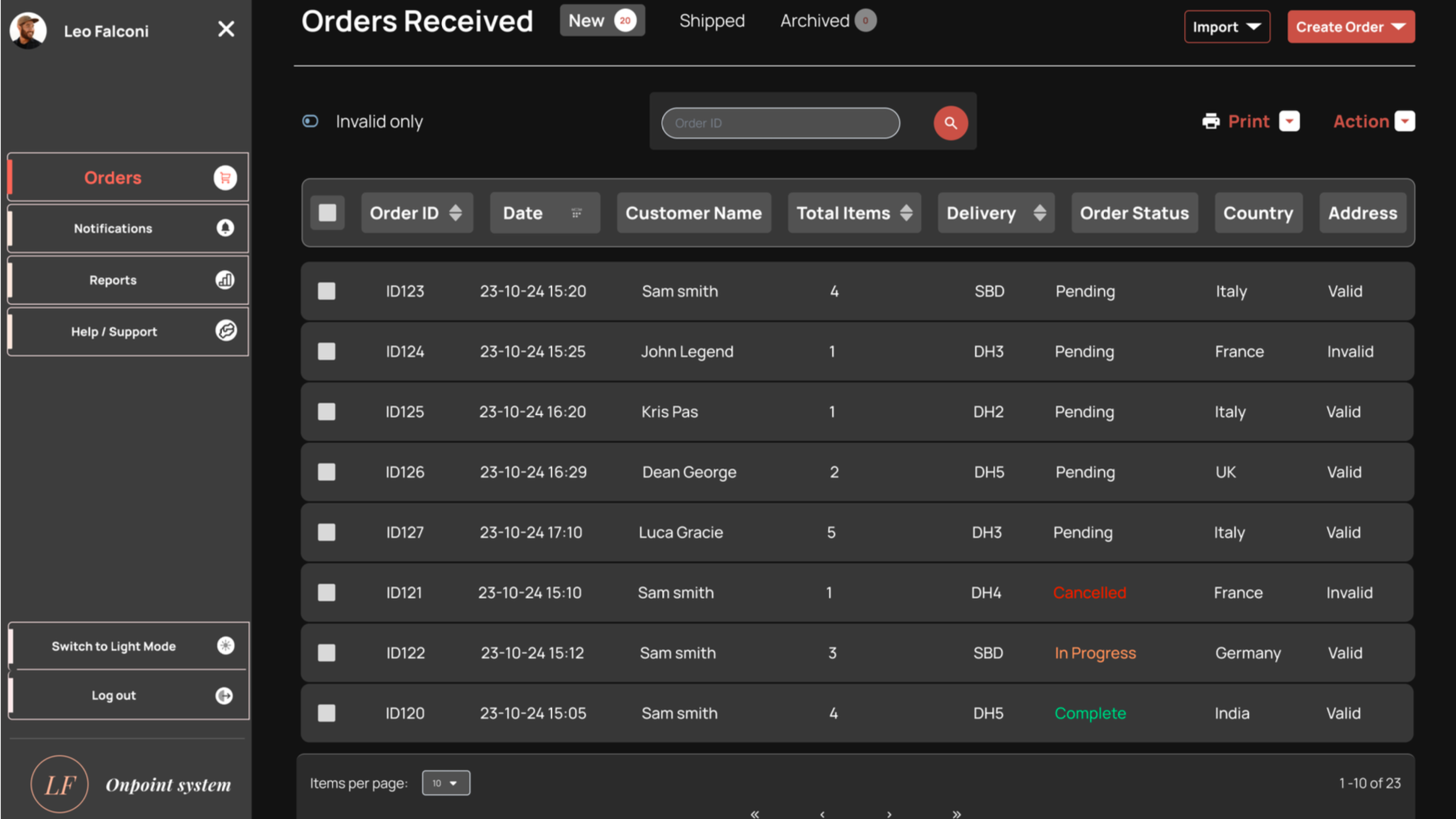

While operators needed mobility, Managers needed visibility. We designed a desktop "Mission Control" to track global inventory velocity and flag issues in real-time.

The Fulfillment

OS.

A bespoke middleware that sits between Shopify and the physical warehouse. It translates digital orders into optimized physical tasks.

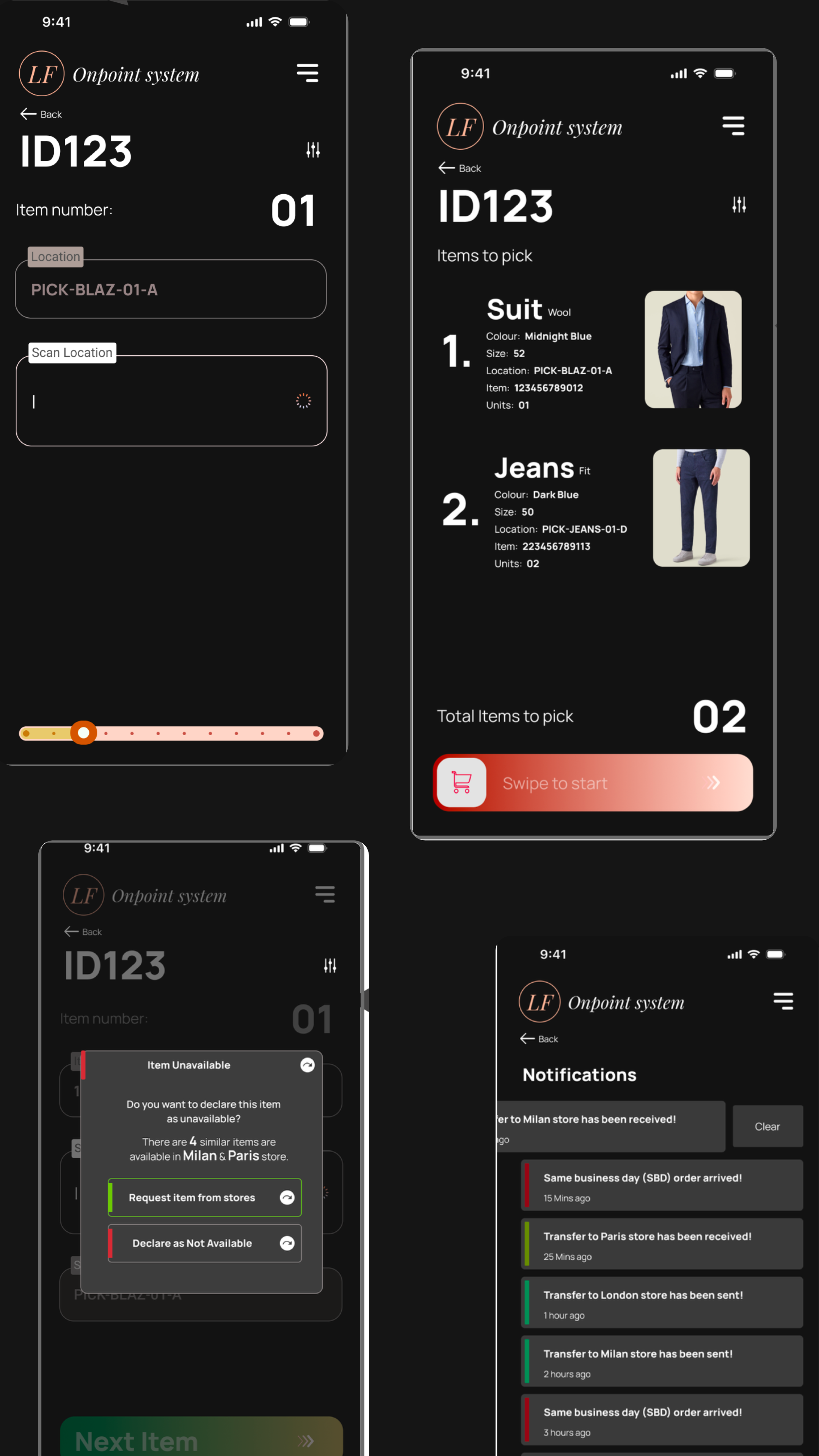

Error-Proof "Pick & Pack"

We designed a high-contrast, big-button interface specifically for zebra scanners.

The app guides the operator to the exact shelf location. They must scan the item to proceed, making it physically impossible to pack the wrong size or color.

- Haptic Feedback for Errors

- Dark Mode for Battery Life

Global Inventory View

Managers moved from disparate Excel sheets to a real-time dashboard. They can now see order status (Pending, Picking, Shipped) across all global warehouses instantly.

We automated label printing logic based on destination, removing the need for manual carrier selection.

Operational

Excellence.

OpEx Reduction

Errors in Packing

Staff Adoption

Fulfillment Speed

Designing for "Gloves"

Designing for a warehouse is different from designing for a cafe. Buttons need to be huge because operators wear gloves. Contrast needs to be high because warehouse lighting is uneven. Accessibility wasn't a "nice to have," it was a requirement for speed.

Change Management

The biggest challenge wasn't the UI, but the habit change. Moving staff from paper to iPads required empathy and training. By involving them in the testing phase ("The Gemba Walk"), we turned skeptics into champions.